Once the firing is complete and the shell has cooled, it is cleaned out. Even coats of microcrystalline wax are heated and poured into the shell as it is slowly rotated. This process is repeated until the wax inside the shell is about 3/16” thick. Next, the waxed shells are submerged in a plaster material, dried, fired in a kiln, and then filled with molten bronze. Finally, once the ceramic and plaster has been chipped away, a bronze copy of the original stick is revealed.

Assistants help Butterfield with the heavy lifting as the first bronze pieces are welded into place, forming the framework for the horse. Then, it’s back to the sticks! Butterfield sorts through piles of wooden sticks and places them, sometimes a few at a time, on the armature where they are secured in place with wire.

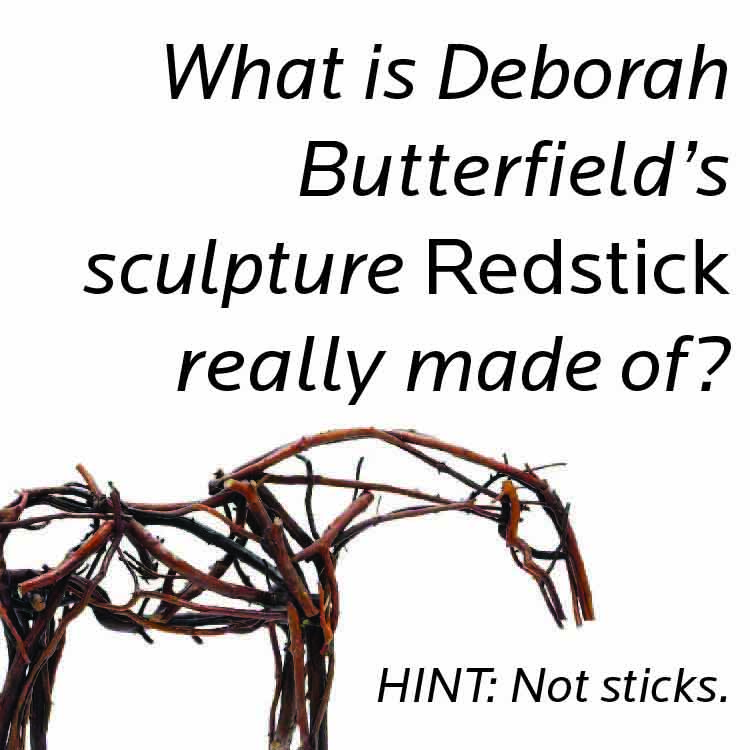

The complete stick and wood form returns to the foundry to be photographed and disassembled. Each stick is cast in bronze and then welded onto the frame work. After that, Butterfield makes some final stick placement decisions, and it’s on to the finishing touches. Texture is tooled into the surface of the sculpture, at which point it is sand blasted, heated to 200 degrees Fahrenheit, spray painted, brush painted, and sealed with hot wax. Et voilà—massive bronze stick horse!

These horse sculptures stand tall (and heavy) as examples of thoughtful composition paired with seamless engineering and a very deceptive attention to detail. So, yes—it really is bronze. The Museum’s curators are not making things up. There were no cut-and-paste errors in the label-making process. Now, stop punching the sculpture.

Butterfield takes a unique approach to sculpting the animal form. Give it a try yourself at Spring Critters this Wednesday, Thursday, and Saturday from noon to 3 p.m. At this drop-in activity, you and your family can create a mini-sculpture in marvelous Model Magic air-drying clay. Check out a full schedule of drop-in Spring Break Specials online.